SMC & BMC COMPOSITES

A composite material is made by combining two or more materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. The two materials work together to give the composite unique properties. The new material may be preferred for many reasons; which are stronger, lighter, or less expensive when compared to traditional materials.

The first modern composite material was fiberglass (FRP) and the most common FRP manufacturing process is hand lay-up (also known as wet lay-up). SMC / BMC are the later developed form of FRP composite material which is widely processed by compression or injection molding.

We develop customized formulations to meet the requirements of specific applications.

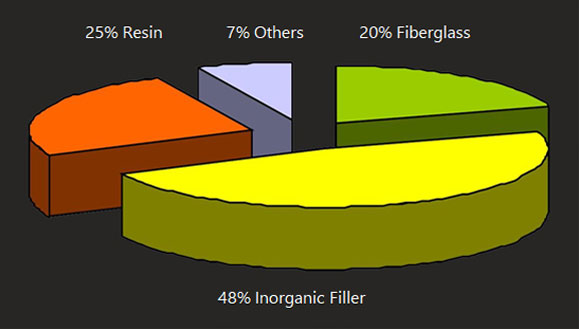

BMC / DMC COMPOSITES

Fiber reinforced (chopped glass fiber) thermoset polyester resin mix of bulk (or dough) form and typically processed by injection or compression molding.

Primarily consists of an amalgam of thermosetting resin, chopped glass fibre reinforcement and filler in the form of a bulk material. The mixing process amalgamates the resin paste, fillers, additives and reinforcements into a mass material with a dough-like consistency

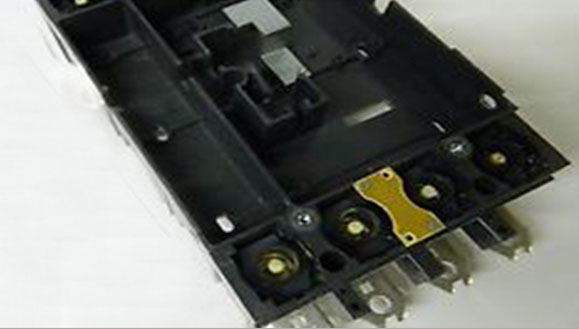

Designed to offer superior mechanical properties, excellent electrical and fire protecting characteristics and capable of processing complex molding shapes.

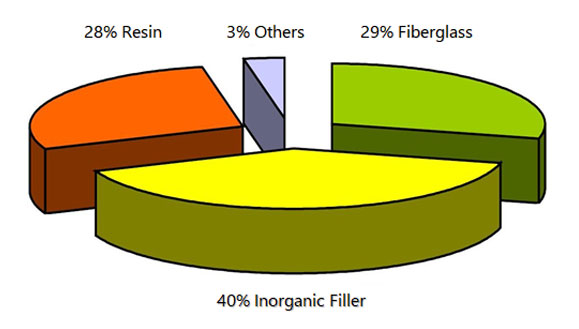

SMC COMPOSITES

SMC (Sheet Moulding Compound) is used in hot press compression moulding for the production of large parts with high mechanical properties and excellent surface finish.

The composite material in a sheet form sandwiched between thin polythene films primarily consists of thermosetting resin, chopped glass fibre reinforcement and fillers. The compacting process amalgamates the resin paste, fillers, additives and reinforcements.

Designed to offer superior mechanical properties, excellent electrical and fire protecting characteristics with a 'Class A' surface and low density features.